Development Status and Prospect Analysis of Hardware Fittings Industry in 2021

Date: 2024-08-02 Categories: Industry News Hits: 1574

China, as the world's largest steel producer and the world's most populous country, has the advantage of low cost of raw materials and labor for manufacturing hardware products, the booming development of China's industry has created a huge demand for hardware, in addition to the continuous development of the national economy, the automobile industry, engineering machinery, agricultural machinery, environmental protection machinery, machine tools, etc., the requirements for hardware, springs and basic parts are getting higher and higher. Product performance, quality, reliability, variety, specifications and requirements are increasingly high. The significant increase in exports in the international market has created an unprecedented huge demand for the hardware industry.

According to "2020-2025 China Hardware Fittings Industry Supply and Demand Analysis and Development Prospect Research Report" by CRRP Research Institute, at present, the hardware industry is running well, the growth momentum of domestic and foreign sales is obvious, the import and export is growing at a high speed, and the economic indicators are improving rapidly, and the industry as a whole basically recovers to the level before the financial crisis. In recent years, China's exports of hardware products to maintain a steady growth trend, China has become the world's hardware processing country and exporting country, with a broad market and consumption potential, is expected to maintain the future annual export volume of 10-15% growth.

The industry is developing rapidly, but there are still defects:

After more than 20 years of reform and opening up, China's hardware industry has made great achievements, which has a positive impact on the world hardware industry and caused the world to pay attention to China's hardware industry. Although our enterprises have made great progress in terms of scale, product quality and innovation ability, there are a lot of problems and big challenges in maintaining sustainable development.

Program Management:

Production plan: the complex structure of the product, the complexity of the manufacturing industry, the product in the various components know the length of the cycle and the uncertainty of the product processing industry process routes, resulting in the management of the object of dynamic change, the uncertainty of the production process increased, but also led to the development of production, procurement plan is very difficult;

Capacity plan: because of the product to semi-finished products are numerous, complex manufacturing industry, so the resulting capacity load conditions often make the ascending management personnel have no way to understand, whether the order can be delivered on time, whether there is still capacity can be arranged for the production of management personnel has become a major problem.

Sales management:

Hardware industry sales model is still the main traditional form of offline business, but the entire market demand for hardware products is very large, too single channel will make us lose a lot of orders, companies need to rely on Internet technology to build a set of omni-channel sales management solutions.

Procurement management:

Traditional procurement of hardware fittings exists market information is not good, large inventory, capital occupation, inventory risk and other shortcomings, often supply exceeds demand and other phenomena, affecting the normal production and business activities of the enterprise, or inventory backlogs, high costs, affecting the economic efficiency of the enterprise traditional procurement mode in the operation and transparency and other aspects of the relative backwardness.

Supplier management:

(1) the lack of effective supplier evaluation system, unable to identify high-quality suppliers, procurement risk is high

(2) and supplier information interaction is not timely, communication efficiency is low

(3) There is no standardized process for supplier qualification and certification, making supervision and management difficult.

(4) Paper-based documents are easy to lose, difficult to achieve management control

(5) Cross-regional and interdepartmental information is not interoperable, unable to share timely procurement information

In a word, it is now a single product, can not adapt to market demand, market competitiveness is not strong, the development of a lack of foresight, relatively blind, small scale, production layout is unreasonable, the existence of disorderly competition, price confusion; low technology, competitiveness is not strong, the market risk is large.

At present, the hardware and machinery manufacturing industry competition day by day sense of competition urgency, the development of the industry is increasingly showing standardization, serialization, intelligence, flexibility, precision and other characteristics. Enterprises have been transformed to resist the speed of market development, increase production flexibility, strengthen cost control, so that enterprises can comfortably cope with a more competitive environment and improve the competitiveness of enterprises.

Translated with DeepL.com (free version)

Industry Transformation, Winning in the Supply Chain Competition among enterprises is essentially competition among different supply chains. With the process of globalization and localization, the supply chain of enterprises is lengthening. Faced with the diversification of orders from customers, increased variety, batch size reduction and shorter delivery time, enterprises want to win in the competition, they must establish a set of agile, rapid response supply chain within the company and between partners. Supply chain management to hardware fittings business processes into a whole, from demand forecasting to sourcing, from manufacturing, to transport transactions to form a complete value chain, so that enterprises on the production cost, inventory and order visualization and management, and close to the real-time data to make rational analysis and decisions, the essence of the superiority of supply chain management is the cost of information to bring about the real cost. Through supply chain demand management, we have a full grasp of the state and trend of the market and customers, and then based on more accurate forecasts, we share demand information with the top of the supply chain, formulate and fine-tune the supply chain plan at any time to ensure smooth production and timely supply, reduce inventory, shorten the lead time for delivery, and improve the delivery rate of the order, and promote the innovation of the management with the investment of information technology, which can be an effective alternative to the traditional push production and dark forecasting caused by high cost. The investment in information technology and the promotion of management innovation can effectively replace the high supply chain costs caused by traditional push production and dark forecasting and reduce the inefficient or exhausted production situation. Internet development promotes the transformation and upgrading of traditional hardware platform. Under the tide of digitalization, it has become the main path for the digital transformation of enterprises to improve the management efficiency and manufacturing level of enterprises by building a digital supply chain platform.

Translated with DeepL.com (free version)

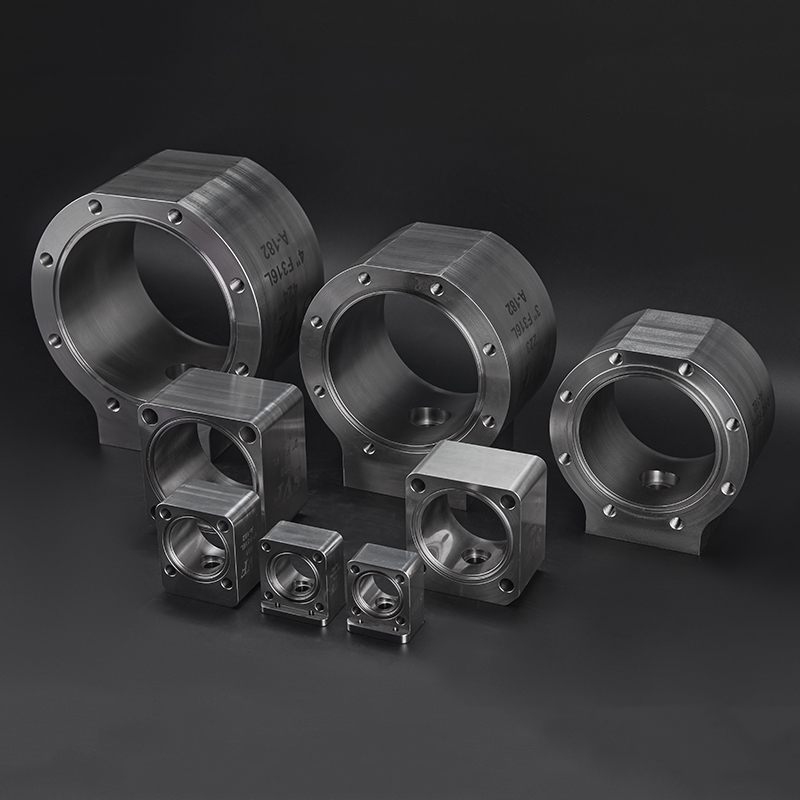

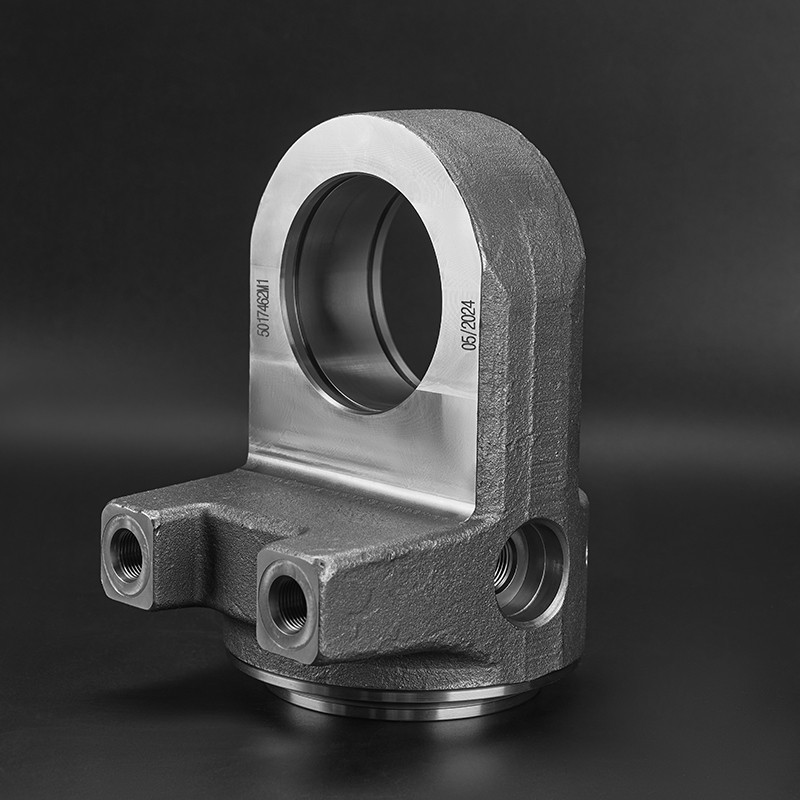

Forging And CNC Machined Hydra...

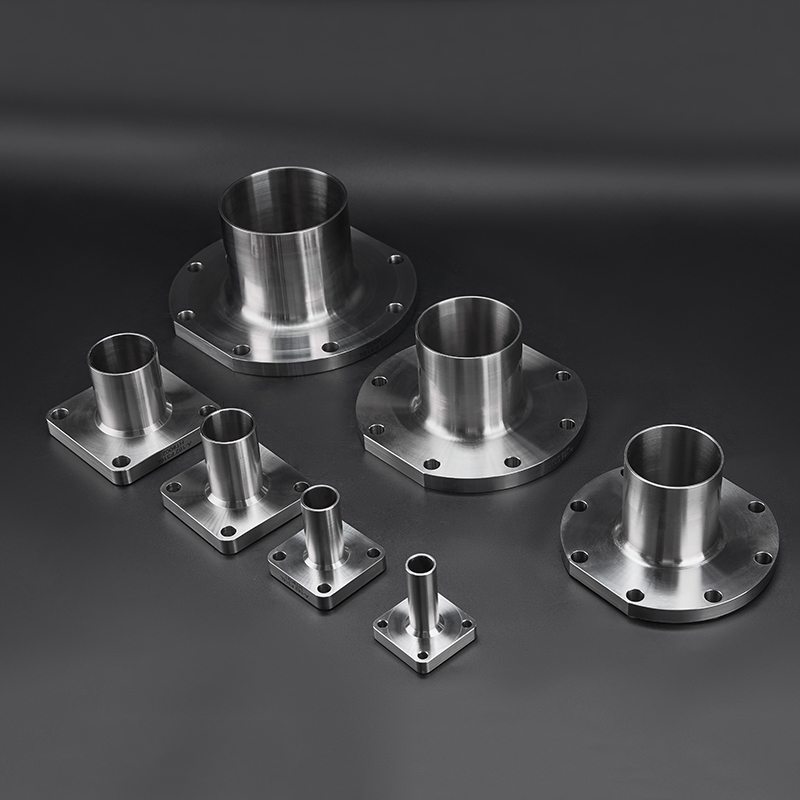

Forging And CNC Machined Hydra...  Forging And CNC Machined Hydra...

Forging And CNC Machined Hydra...  Forging And Turning Machined V...

Forging And Turning Machined V...  CNC Machined Hardware Tool Acc...

CNC Machined Hardware Tool Acc...  Forging And CNC Machined Hydra...

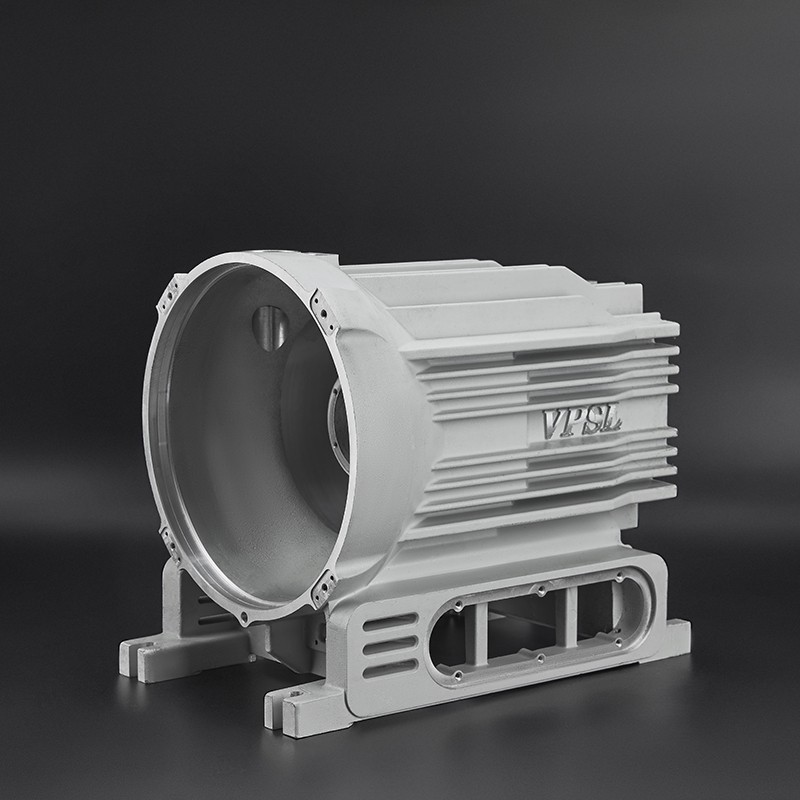

Forging And CNC Machined Hydra...  Gvavity Casting Vacuum Pump Mo...

Gvavity Casting Vacuum Pump Mo...  Gravity Casting Hardware Tool ...

Gravity Casting Hardware Tool ...  Die Casting Auto Parts

Die Casting Auto Parts  Die Casting Auto Parts

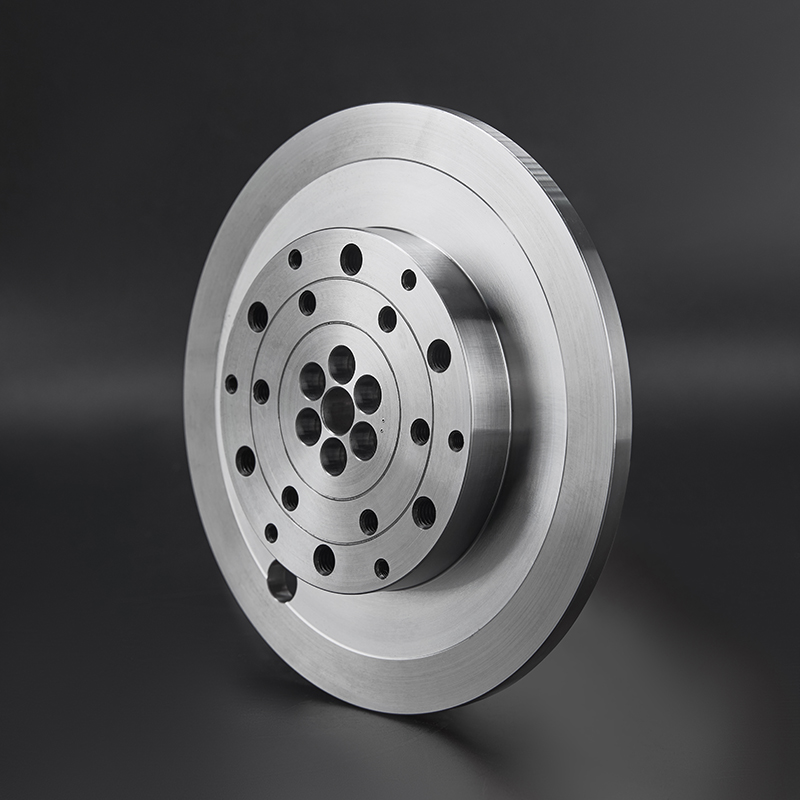

Die Casting Auto Parts  Sand Casting Auto Parts Pulley

Sand Casting Auto Parts Pulley  Forging And CNC Machined Hydra...

Forging And CNC Machined Hydra...  Forging And CNC Machined Hydra...

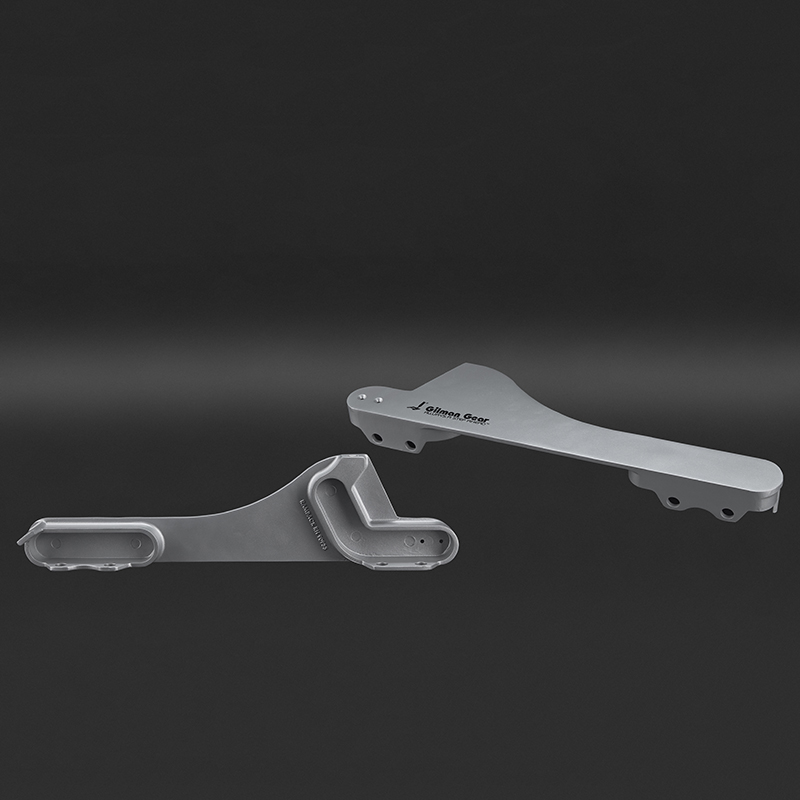

Forging And CNC Machined Hydra...  Forging Scooter Accessories

Forging Scooter Accessories  Sand Casting And CNC Machined ...

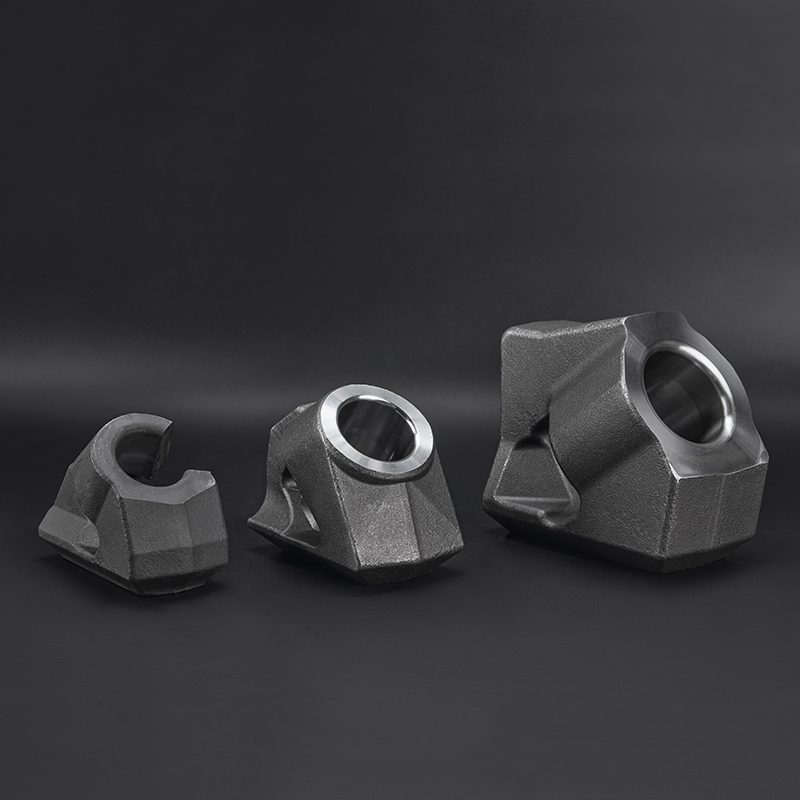

Sand Casting And CNC Machined ...  Forging Engineering Machinery ...

Forging Engineering Machinery ...  Forging And Turning Machined V...

Forging And Turning Machined V...  Forging Hardware Tool Accessor...

Forging Hardware Tool Accessor...  Die Casting Motor Accessories

Die Casting Motor Accessories